WINE CELLARs

Contact us to have a Wine Cellar designed and built for you!

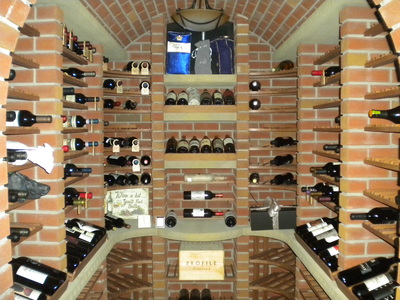

Brick wine cellar

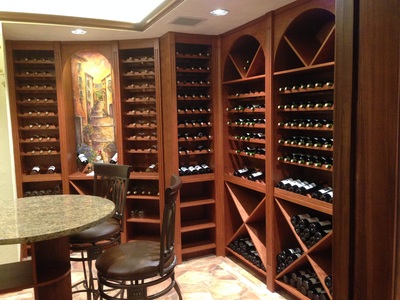

contemporary wine cellar (cherry wood)

stone wine cellar

traditional wine cellar

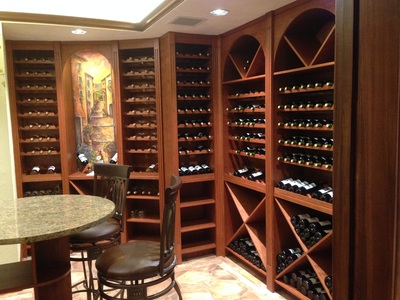

TRADITIONAL WINE CELLAR

wood wine bottle tags

Do you have any “Good” bottles of wine in your wine cellar? Hanging one of those paper or plastic tags on it just doesn’t feel right! Well…these reusable, solid Maple, tags are what you are looking for. They make those bottles look as special as they will taste while they sit in your racking! They even make a “Not so good bottle” look great! Actual size: 3 7/8"Tall X 2"Wide X ~3/16"Thick (1 3/8" Hole diameter) with a High-Gloss epoxy finish.

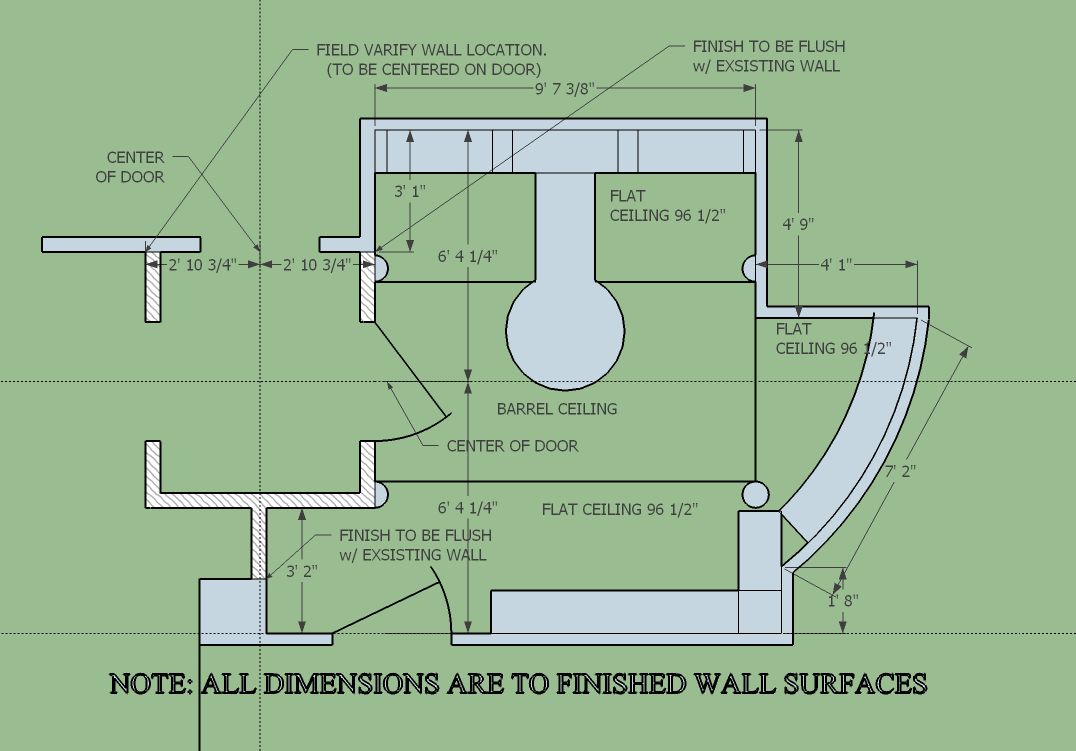

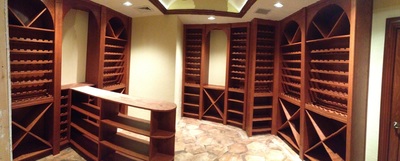

The Building Process of a Wine Cellar

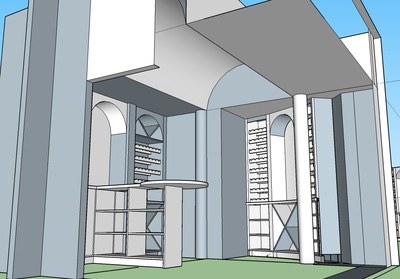

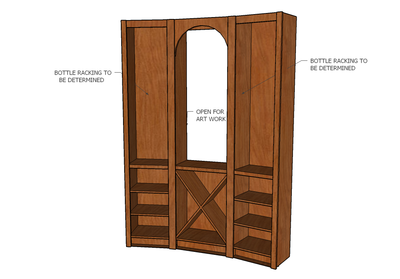

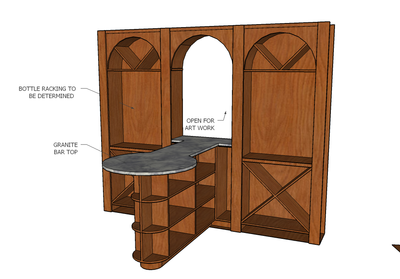

The three designs below are of “3D” views of the racking areas. These are just a few of the designs provided to the client so that he would be able to see what the finished cabinets will look like.

construction of the cabinets begins

As I am building the cabinets, a general contractor is preparing the framing to the specifications of the design.